Aluminum Competitive Issues: Environmental Issues

Environmental Issues

Environmental Issues

International Competition

Major Products and Markets

Regulations and NOx Control

Summary

Trends / Major Products

Trends / Employment and Productivity

Trends / Energy Consumption by Fuel

Trends / Primary Aluminum Production

Trends / Total Supply of Aluminum

Trends / World Aluminum Output

Trends / Distribution of Power Plants

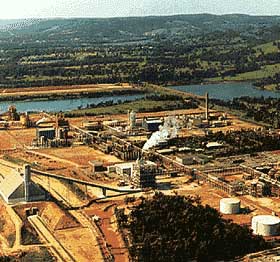

Trends / Distribution of Processing Plants

The costs associated with reducing sulfur dioxide emissions required by electric utilities under the Clean Air Act of 1990 could jeopardize the supply of cheap electricity to primary aluminum smelters. Also, measures to curb greenhouse gas emissions could impact aluminum smelters since half of the aluminum produced in the U.S. uses power from coal burning power plants, a principal source of greenhouse emissions. Enforcement of these regulations could potentially shift more primary aluminum production off-shore to countries were inexpensive power is available.

The secondary processing of aluminum into consumer products is not heavily dependent upon electricity consumption, but upon natural gas consumption. Increasing environmental controls on natural gas furnaces and ovens to curtail oxides of nitrogen (a precursor to atmospheric ozone) are beginning to impact secondary aluminum processing companies located in EPA ozone non-attainment areas. As the Clean Air Act of 1990 begins to be enforced, secondary aluminum processing plants will be forced to adopt lower polluting aluminum processing equipment. Enforcement of these regulations will probably not impact the total domestic production and manufacturing of consumer aluminum products. Companies will be motivated to either relocate to less environmentally sensitive areas of the U.S. or replace existing gas fired equipment with electric equipment.

A major environmental issue is the disposal of spent pot liners due to cyanide and fluorine contamination. Reynolds Metals is working on rotary kiln technology and the Institute of Gas Technology is working on a cyclonic combustor to convert slag. These environmental clean up technologies represent a potential new gas load at primary aluminum smelters.