Navigation Panel

Heat Treat Overview

Heat Treat Chemistry

Batch Furnace

Continuous Furnace

Vacuum Furnace

Atmosphere Generators

Aluminum

Flame Heat Treat

© ESC TechPro 2002-2015

Heat Treat Aluminum

Applications

The most common purpose of heat treating aluminum is to reduce the stresses of machining and shaping. The most common process is Annealing. Other processes are for corrosion resistance and other special surface treatments, such as wear resistance and appearance.

The most common purpose of heat treating aluminum is to reduce the stresses of machining and shaping. The most common process is Annealing. Other processes are for corrosion resistance and other special surface treatments, such as wear resistance and appearance.

Heat Treatment

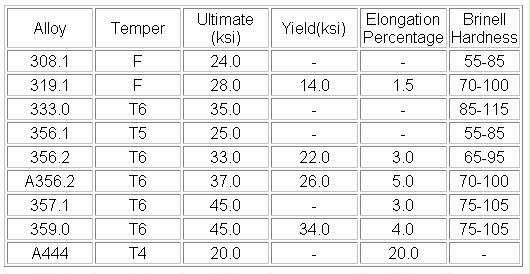

Heat treatment of permanent mold aluminum castings improves the mechanical properties. This improvement in the casting’s strength enhances the design options available to the engineer.

Although there are many variations of heat treatments available, the normal heat treatment descriptions for permanent mold castings are:

- T4 – Solution heat with quench

- T5 – Artificial aging

- T6 – T4 followed with a T5 aging

Mechanical properties can be improved through the casting design and heat treatment. The properties listed are standards from the Aluminum Association.

Sources: TechPro DTE Energy 2001; Aluminum Association web site 2001

© Energy Solutions Center Inc. All Rights Reserved