Direct Reduction: R&D Trends

|

“Direct from the Midrex”, Midrex Direct Reduction Corp. Publication, Vol. 20, No. 4, 1995. |

Equipment

Combustion Technology

Energy Consumption

Process Description

R&D Trends

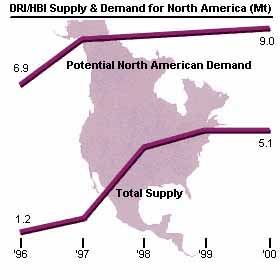

Blast furnaces have dominated the ironmaking scene for decades. These furnaces have gone through many improvements, and continue to do so. However, the capital intensive nature of integrated steelmaking, and increasingly burdensome and expensive environmental regulations suggest that future significant technological advances with these furnaces will be limited. Advances are likely to involve DRI, HBI, Iron Carbide and other direct ironmaking/steelmaking processes.Currently within the U.S., projected demand for DRI far outstrips supply. In 1994, the U.S. imported more than twenty times the DRI it produced, 1,102,441 net tons imported versus 53,308 exported. Roughly 88.4% of the U.S. imports of DRI originated in Venezuela. In the U.S., there is one captive DRI production facility operated by Georgetown Steel (Georgetown, S.C.) with several DRI/HBI projects in the works.

Projections indicate that electric furnace output could rise to as much as 40-45% of total world steel output by 2000. As electric furnace steelmaking becomes more efficient and casting technologies advance, the availability of low residual scrap decreases. These operations will have to look increasingly toward DRI to replace diminishing scrap supplies. This will be especially true to the minimills and other electric furnace operations that will find it almost impossible to produce high quality steel products with steel made from 100% scrap.

Nucor has invested $60 million in an iron carbide production plant in Trinidad whose goal is to produce 320,000 metric tons/year of iron carbide for the furnaces at its two existing flat rolling plants (Hickman and Crawfordsville). The iron carbide will replace 20% of the low residual scrap requirements and increase the quality of the steels produced. The plant has been completed, but early reports have indicated start-up problems associated with auxiliary equipment that has reduced the initial output to less than 40% of design. Initial iron carbide product is being tested at the Nucor Hickman plant EAF.

Hogan, W.T, 1994, “Steel in the 21st Century: Competition forges a new world order”, Lexington Books, New York

1994 Annual Statistical Report, American Iron and Steel Institute.

Iron and Steel Engineer, June 1995.

Iron and Steel Engineer, April 1995.