Electric Arc Furnace: Equipment

|

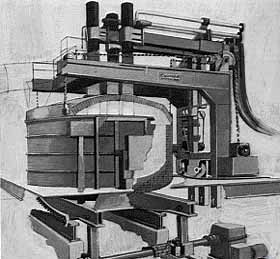

Heroult electric arc furnace, cut away to show sections of the bottom, sidewall, and roof. |

Equipment

Combustion Technology

Energy Consumption

Process Description

R&D Trends

The most common configuration for the EAF in the steel industry is circular with a dish shaped hearth. A typical direct three phase AC furnace has three movable graphite electrodes mounted in the roof. The roof is typically removable for scrap and flux charging. After charging, the electrodes are lowered just above the scrap and an arc is struck that provides the heat for melting the scrap primarily through radiation but also through the current resistance through the metal. Scrap can be added several times during a cycle. The largest EAF in the U.S. is capable of providing 370 tons/melt; average for the steel industry is 50-150 tons/melt, with certain specialty and foundry applications being much smaller. Tap-to-tap times vary as a function of power input and refining requirements from 1 to 5 hours per melt.Fume and Dust Collection System

All EAFs have a dust collection and gas clean-up system attached to the furnace. Various systems are used including baghouse, dust collector, sidedraft, direct evacuation, fourth hole systems, and wet scrubbers.

Oxygen Lancing

Oxygen lancing is used on some furnaces to increase the rate of carbon removal from the melt. This practice is often accompanied by coke or coal injection to first increase and then decrease carbon to achieve a controlled product specification.

Water Cooled Panels

Replacement of sidewall and/or roof refractories with water cooled panels decreases the cost and downtime associated with refractory replacement and allows an increased rate of power usage in the furnace thereby increasing productivity.

Oxy-fuel burners

Oxy-fuel burners are used on about half the EAFs in the US. They increase the effective capacity of the furnace by increasing the speed of the melt and reducing the consumption of electricity and electrode material.

Electrode Saver Equipment

Typical electrode control moves the electrodes in place based on sensed arc voltage and current flows. This type of control can lead to electrode breakage if there is excessive slag or other nonconductive material in the melt. Electrode saver equipment combines current and voltage control with a mechanical tension sensor that stops the mast motor in cases of abnormal tension.

Power Demand Control

EAF meltshops can control electric power demand and thus reduce costs by controlling furnace operation so as to minimize power demand spikes and power factor corrections.

UHP Transformers

Transformer ratings per ton of steel melted have increased dramatically over time. Some shops have over 700 kva/ton of steel of capacity. Three legged transformers are also used that can individually control voltage for each phase to control furnace hot spots while maintaining maximum power input.

Static VAR Generators

EAFs create power quality problems in terms of power factor adjustment and flicker. Some shops are turning to static VAR generators to control power factor and flicker and thus reduce utility charges.

Bottom Tapping

In Germany, several furnaces have the taphole located in the furnace bottom. When the heat is ready to tap, a plug is removed and the heat is tapped in less than a minute. This design feature can reduce tap times by 3-7 minutes and better slag control can be achieved.

Materials Handling

Tap to tap times of 90 minutes have become commonplace for new UHP meltshops. New methods for automatic scrap and flux handling are being developed that keep pace with the faster operating cycles.

Scrap Preheating

Used extensively in Japan, the use of hot furnace gases for scrap preheating is now being used in the US. Scrap preheating can save 4-50 kWh/ton and reduce tap-to-tap times by 8 to 10 minutes.

DC Arc Furnace

Pioneered in Europe, single electrode furnaces operating on direct current have recently been commercialized in North America. This design reduces noise and electrical flicker, increases efficiency, and reduces electrode consumption. There are eight DC power EAFs operating in the U.S. and one in Mexico; most have been installed in the last two years, the oldest was installed in 1991. The manufacturers involved are Fuchs, NKK/United, MAN Ghh, and Voest-Alpine.